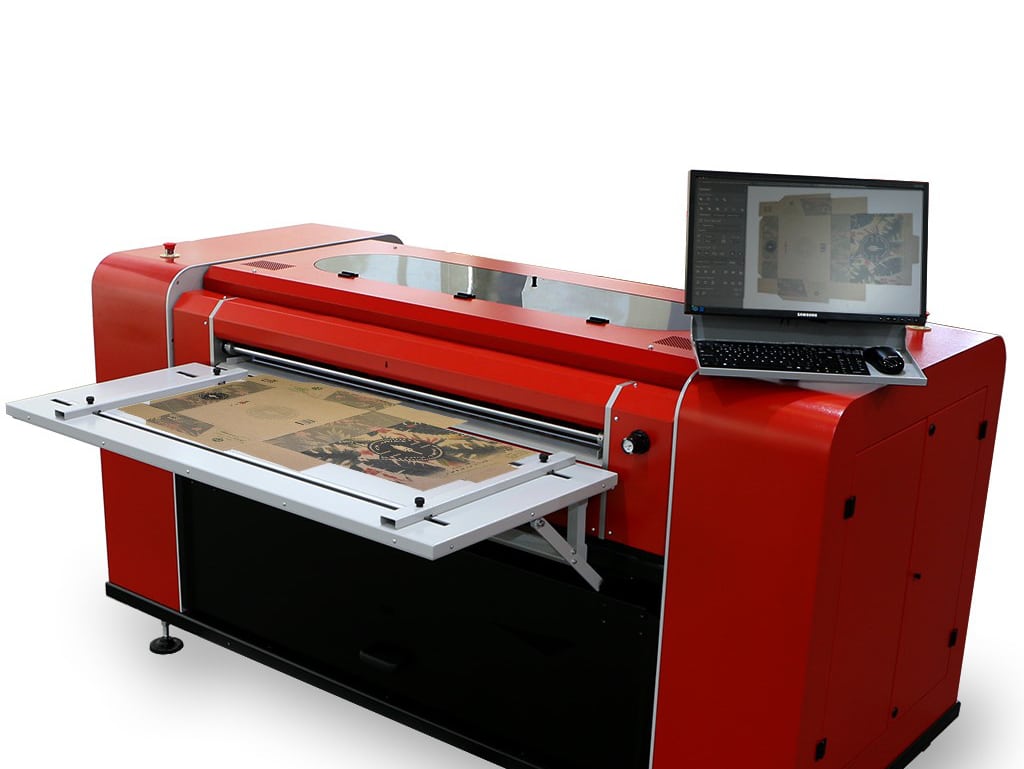

Digital Print it. Be Unique! – With our new digital printer, we can supply from 1 to 1000 custom printed boxes. Short lead times. Ideal for E-commerce packs, Subscription boxes, Business start-ups, Prototype packs & many more.

We can make any style specifically for you, an exact sized box reduces the need for void fill and offers superior protection.

Trusted by an ever increasing customer base to deliver the right solutions, quickly and at reasonable prices over the last 25 years. We are based in Letchworth, Hertfordshire and love to help our clients solve packaging problems.

Some of the companies who use Barton Jones for their packaging requirements.

You can browse our available products online. If you’re unsure of what you need, please get in contact with our team of experts who are always happy to assist!

Our wide range of E-Commerce packaging designs are high-quality, priced sensibly and are suitable for even the most demanding online retailers.

Contact us with your design brief or just give us a call and our team will be delighted to assist you. Get Started

See what our clients have to say...

Verified Reviews for Barton Jones Packaging Ltd

40k +

Products shipped per day

98%

Products are Recyclable

5.0/5.0

Customer ratings on Google

Find out about our range of Eco-Packaging that is not only great for your safely shipping products, but it’s also kind to the planet.

Browse Eco Packaging